Welcome!

Industar e-shop

All prices include VAT *

Spartus Apollo 500 Laser cutting machine CNC (3000W)

SPARTUS APOLLO 500 LASER CUTTER – CUTTING PRECISION FOR MODERN PRODUCTION

CONCENTRATED POWER AND HIGH QUALITY

SPARTUS Apollo 500 is a modern fiber laser cutter with 3 kW power, designed for precise sheet metal cutting. The integrated Raycus laser source and Raytools BM110 cutting head with autofocus ensure not only excellent cutting quality but also long service life and stable operation even in intensive production conditions.

COMPACT AND STABLE DESIGN

The Apollo 500 is built on a reinforced, welded frame that is precisely machined to the highest standards. Its gantry-type design with rack and pinion drive ensures rigidity, vibration resistance, and excellent dynamics. The traverse made of cast aerospace-grade aluminum guarantees durability and resistance to deformation.

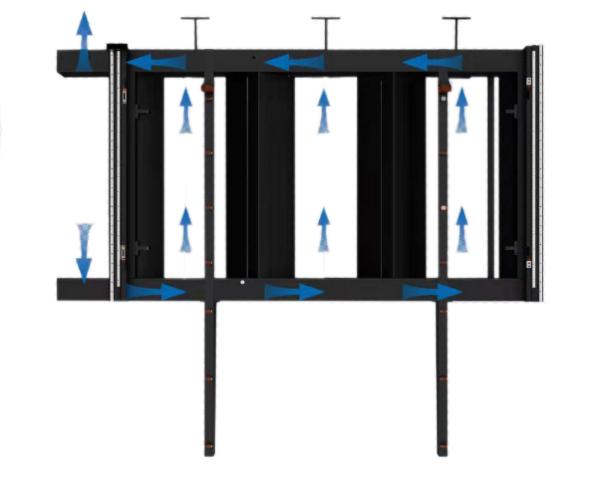

EFFICIENT EXTRACTION SYSTEM AND ENCLOSED BODY DESIGN

The enclosed design is equipped with a zoned extraction system – air is supplied from one side and exhausted from the other. This construction allows for efficient removal of fumes and dust directly from the cutting area, ensuring cleanliness, safety, and protection of optical components.

HIGHLY DEVELOPED OPTICS FOR DEMANDING APPLICATIONS

Raytools BM110 is a cutting head designed for intensive use, equipped with autofocus, enhanced lens cooling, and four protective lenses.

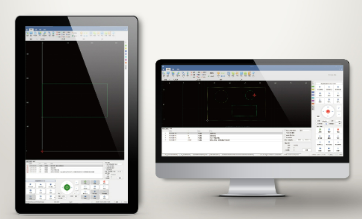

INTUITIVE CONTROL AND COMPLETE MANAGEMENT

Raytools X3S is an industrial-grade control system with full CAD/CAM/NEST integration. It provides automatic drawing error correction, cutting optimization, and improved production planning. The 21” screen allows quick access to all functions, while built-in statistical tools and motion error compensation guarantee repeatable results.

VOLTAGE STABILIZER – POWER SAFETY AND RELIABILITY

SPARTUS Apollo 500 is equipped with a 40 kVA voltage stabilizer, which plays a key role in ensuring the safe and stable operation of the device. It automatically adjusts the supply voltage to local power grid conditions, regardless of country or region. Voltage stabilization and regulation protect electronic systems from voltage fluctuations and disturbances, increasing the durability of components and the overall reliability of the laser system.

DESIGNED FOR PERFORMANCE AND USER CONVENIENCE

The Apollo 500 is designed with user convenience in mind: the worktable with side sliding function allows for easy loading and unloading of materials, while the built-in automatic lubrication system and visual monitoring support continuous operation. Electrical components from Schneider Electric, PEK guides, Atlanta gears, and Leitesen rack rails ensure high durability and reliability.

PERFECT CUTTING SAMPLES

The Apollo 500 excels in cutting thin-walled parts, sharp corners, and micro-holes. It delivers shiny and clean edges. This solution meets the needs of demanding industrial applications, where not only speed but also top-tier quality matter.

Technical Information

| Working area | 3000 x 1500mm |

| Laser power | 3000W (Raycus) |

| X axis range | 1500mm |

| Y axis range | 3000mm |

| Z axis range | 100mm |

| Maximum positioning speed (XY) | 100m/min |

| Maximum positioning speed (total) | 100m/min |

| Positioning accuracy | ±0.02mm/m |

| Maximum acceleration value | 1.3G |

| Positioning repeatability | ±0.03mm/m |

| Laser source | Raycus |

| Automatic focusing | yes |

| Display | 21-inch vertical display |

| Control system | Raytools X3S |

| Beam guide | aluminum |

| Cutting head | Raytools BM110 Autofocus |

| Cooling | cooler |

| Rack and pinion | LEITESEN |

| Linear guides | PEK |

| Maximum table load | 1500kg |

| Total machine weight | 3800kg |

| Dimensions | 5125x3975.8x2871.45mm |

Related products

Cart

Cart is empty.